Understanding Steel Structure Integrity in Challenging Environments

Why Steel Structures Are Increasingly Popular in Scenic and Tourist Areas

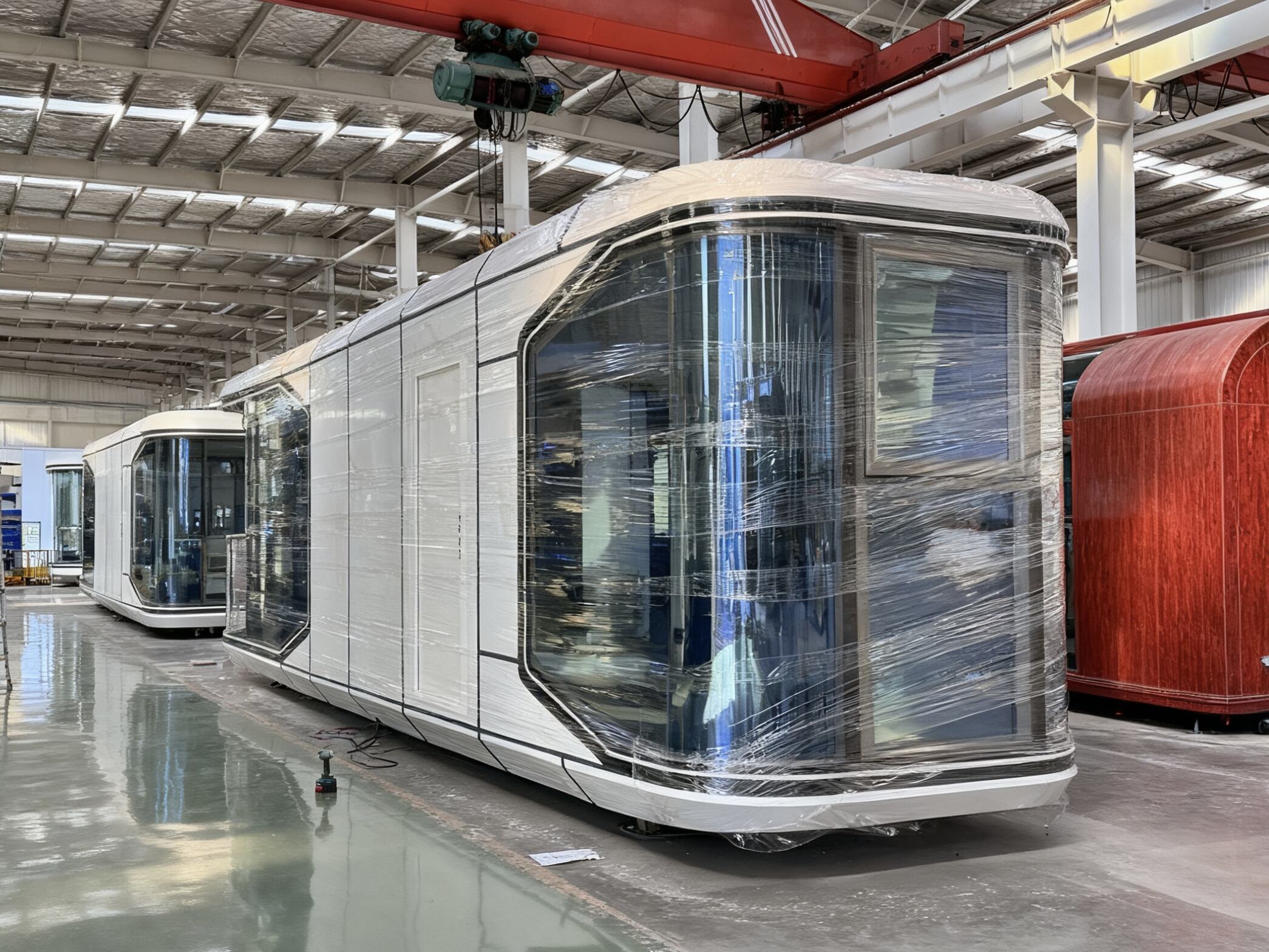

Steel has become pretty popular for those scenic structures because it's strong yet light, plus it works well in places where environmental sensitivity matters. Take prefabricated steel cabins for instance. According to a study from Construction Materials Journal last year, these need about 40 percent less digging for foundations compared to regular concrete buildings. That makes all the difference when working near delicate spots such as cliff edges along coasts or up in the mountains. The modular nature of steel construction means workers can put things together even on rough ground without bringing in big machines. Think about those walking paths suspended above valleys or viewing platforms perched at mountain peaks where traditional methods just wouldn't work.

Core Principles of Structural Integrity Under Environmental Stress

Three key factors ensure steel performs reliably under extreme conditions:

- Load distribution: Engineered truss systems redirect wind and snow loads to reinforced anchor points

- Corrosion resistance: Hot-dip galvanized coatings provide over 50 years of protection in humid or marine climates

- Thermal compensation: Expansion joints prevent warping across temperature extremes (-40°F to 120°F)

Steel's natural flexibility allows 6–8% elastic deformation without permanent damage, making it ideal for earthquake-prone regions.

Case Study: Performance of Steel Cabins in Mountainous National Parks

During the 2023 Sierra Nevada snowstorms with 287 inches of accumulation, steel-framed ranger stations showed no structural deformation, compared to 23% of timber structures requiring repairs. Diagonal bracing maintained roof integrity under 185 PSF snow loads, while ventilated wall cavities prevented ice dam formation.

Designing for Load-Bearing Capacity Across Diverse Scenic Applications

| Application | Load Consideration | Steel Solution |

|---|---|---|

| Cliffside Observatories | Wind uplift (130 mph gusts) | Aerodynamic roof profiles + ground anchors |

| Treehouse Walkways | Dynamic visitor loads | Open-web joists with 300% safety factor |

| Glacier View Platforms | Thermal contraction (−80°F) | Slotted bolt connections + thermal breaks |

Engineers use topology optimization software to reduce material weight by 15–30% while maintaining load capacity—essential for remote sites requiring helicopter transport.

Compliance with International and Local Steel Structure Safety Standards

Key Requirements from the International Building Code (IBC) for Steel Structures

Steel structures built in scenic spots must follow strict guidelines from the International Building Code. Wind, snow, and earthquake forces need careful calculation, particularly important when buildings stand on mountainsides or near coastlines where weather conditions can be extreme. The code's Section 2205 demands special coatings that resist rust for any steel parts likely to get wet or hit by sea spray. Meanwhile, Chapter 16 lays out what kind of materials should be used and how welds need to be done so everything stays intact over time. Looking at actual construction projects across beautiful landscapes shows these rules work well in practice. A study last year checked 120 different scenic area developments and discovered that almost all (about 92%) of those following IBC standards didn't need fixing within five years of completion.

AISC Standards and Their Role in Ensuring Steel Frame Safety

The American Institute of Steel Construction, or AISC as they're commonly called, adds extra layers to what the International Building Code already requires when it comes to how steel gets fabricated. Take AISC 303-22 for instance. This document sets really strict limits on bolted connections, allowing only about 1.5 millimeters of variation either way. And if there are welds holding up weight? They want ultrasonic tests done on those too. Why does this matter so much? Well consider something like an elevated observation deck. If builders don't get the torque right on those bolts, problems happen. According to the 2022 Construction Safety Report, almost 4 out of every 10 safety issues at these kinds of sites were traced back to wrong torque settings in structures that didn't follow the rules properly.

Navigating Local Regulations in Sensitive or Remote Scenic Zones

International building codes provide a starting point, but around three out of four UNESCO protected areas actually have extra rules in place. For instance, mountainous areas typically want columns that narrow towards the top so they don't stick out too much visually. Meanwhile, places near the coast insist on special treated steel that can withstand salt water exposure for at least two whole work weeks. Getting ecological groups involved early makes all the difference when dealing with things like how deep foundations need to go in freezing climates or making sure animal migration paths stay open through forested areas. A recent look at construction projects from last year showed something interesting too: those following both standard IBC guidelines plus local regulations faced about half as many delays during approvals as projects that just went with basic standards.

Compliance Tip: Implement BIM clash detection during design to pre-resolve 89% of regulatory conflicts before construction (2024 AEC Industry Benchmark).

Wind, Seismic, and Extreme Weather Resistance in Steel Homes

How Steel Frame Systems Withstand High Winds and Seismic Activity

The flexibility of steel combined with its impressive strength relative to weight means buildings made from it can bend when stressed instead of breaking apart completely. This matters a lot in places where hurricanes hit regularly or earthquakes are common. Today's steel frames handle winds over 150 miles per hour easily enough for category four hurricanes on the scale. They also absorb about forty percent less energy from shaking compared to other materials that don't flex as well. When something hits these structures hard, the force gets spread out across the whole framework rather than concentrating in one spot which helps prevent major deformations. The Federal Emergency Management Agency reported last year that buildings built with steel suffer roughly sixty two percent less damage overall after experiencing earthquakes measuring seven point zero or higher on the Richter scale versus similar sized concrete structures.

Case Study: Steel Homes Surviving Hurricanes in Coastal Viewpoints

In the Florida Keys, steel homes have demonstrated exceptional resilience. A 2022 post-hurricane survey revealed that 97% of steel-framed vacation cabins survived Category 4 storms intact, versus 53% for timber structures. Success factors include:

- Continuous load paths transferring wind forces directly into foundations

- Impact-resistant cladding rated for 200 mph debris

- Elevated pier foundations mitigating storm surge risks

These engineered solutions confirm steel's suitability for high-risk scenic developments requiring minimal post-storm maintenance.

Design Strategies for Enhanced Resilience Using Bracing and Damping Systems

Advanced bracing systems—such as eccentric and knee braces—improve wind resistance by 30–50%, while tuned mass dampers reduce seismic vibrations by 65% in multi-story lodges. When combined with other technologies, these systems significantly boost performance:

| Strategy | Performance Benefit | Implementation Cost |

|---|---|---|

| Cross-bracing | +45% lateral stability | $$-$$$ |

| Friction dampers | 55% vibration reduction | $$$-$$$$ |

| Galvanized coatings | 75+ year corrosion resistance | $-$$ |

This layered approach ensures long-term safety in exposed environments such as coastal bluffs or high-altitude resorts.

Material Quality and Corrosion Protection in Exposed Climates

Scenic-area steel structures face harsh exposure to humidity, saltwater, and temperature swings. Long-term durability depends on strict adherence to material standards and advanced corrosion defenses.

Essential Material Standards and Testing for Scenic Area Installations

The standards ASTM A500 and AISC 360-22 set the bar for what counts as good quality structural steel, basically saying that anything holding up weight needs to have at least 50 ksi (or 345 MPa) yield strength. To make sure these materials can actually stand up to real world stress, independent labs run all sorts of tests. One common method involves salt spray chambers that speed up corrosion processes, essentially mimicking what happens when steel sits near the ocean for half a century according to NACE TM0169 guidelines. When dealing with structures built high up where temperatures drop below freezing, there's another test called cryogenic impact testing done at minus 40 degrees Celsius. This helps determine if the metal will crack under extreme cold conditions that might be encountered at elevations over 2000 meters.

Corrosion Prevention Techniques for Humid, Marine, and Alpine Environments

Hot dip galvanization with at least 5.8 oz per square foot of zinc coating can protect metal surfaces for more than 40 years even in salty coastal air. Epoxy polyurethane hybrids work well too, standing up to sun damage when used at higher elevations where UV exposure is intense. For parts made from different metals working together, sacrificial anodes of either magnesium or zinc help stop the kind of corrosion that happens between dissimilar materials. Along coastlines specifically, using bolts that meet ASTM A123 standards along with PTFE gaskets creates a barrier against those tricky crevice corrosion problems that tend to develop in tight spaces between components.

Long-Term Weather Resilience of Steel in Extreme or Elevated Conditions

Once that protective patina starts forming on metal surfaces, atmospheric corrosion really slows down. Take A588 weathering steel for instance it only corrodes at less than half a mil per year in those high altitude alpine areas according to NIST research from 2023. Down in the desert where temperatures can swing by 50 degrees Celsius day to night, engineers install thermal expansion joints roughly every 40 meters along structures. These joints help keep things from cracking under all that heat stress. And when building up there in the mountains above 3,000 meters elevation, construction crews turn to ASTM A514 steel instead. Why? Because this particular alloy keeps about 90 percent of its strength intact even when temps drop below minus 60 degrees Celsius. Makes sense for anyone working in extreme climates.

Foundation, Roofing, and Connection Systems for Maximum Stability

Secure Foundation and Anchoring Solutions for Rocky or Unstable Terrain

Foundations designed specifically for tough terrain really make all the difference when it comes to structural stability. When dealing with rocky areas, drilling piers about four to six feet deep into solid bedrock provides much better support than regular shallow footings. Studies from Geotechnical Engineering Today in 2023 show this method can reduce settlement issues by as much as two thirds to four fifths. For places where the soil isn't so stable, combining helical piles with grade beams works wonders too. These systems spread out the weight across different points and actually handle small shifts in the ground pretty well without causing problems. Some of the main techniques used for anchoring structures include...

- Galvanized steel ground anchors with 25% higher pullout resistance

- Cross-bracing for lateral stability in seismic zones

- Adjustable permafrost-resistant footings for alpine regions

Roofing Design and Snow Load Management in Cold Climate Scenic Areas

Steel roofs handle snow loads up to 150 psf through optimized truss spacing (¤24") and double-layer decking. Effective strategies include:

- Roof pitches between 30°–45° with ice-resistant coatings to minimize buildup

- Composite panels providing R-30 insulation for operation at -40°F

- Continuous snow guards enabling controlled shedding

Bolted vs. Welded Joints: Safety and Durability in Remote Steel Assemblies

In scenic areas where installation speed matters and ground conditions can change unexpectedly, bolted connections tend to be the go to choice. Research from field tests indicates that these bolted joints keep about 97 percent of their strength even after sitting out for ten whole years along coastlines. That's pretty impressive when we compare it to welded joints which only manage around 89% according to Materials Performance study last year. For structures that need extra stability though, especially those built to withstand earthquakes or placed in areas with strong winds where continuous support is critical, welding still holds its own as the best option despite the longer setup time required on site.

Integrating Reinforced Concrete and Composite Materials for Enhanced Stability

Hybrid systems enhance performance: concrete-filled steel tubes (CFST) increase compressive strength by 40% in avalanche-prone areas. Composite floors combining steel beams and precast slabs achieve 30% greater fire resistance than conventional designs. For ecologically sensitive elevated walkways:

- Glass fiber-reinforced polymer (GFRP) decking reduces corrosion and maintenance

- Rubber-isolated connections dampen vibrations from pedestrian traffic

FAQ

Why are steel structures used in scenic and tourist areas?

Steel structures are preferred in scenic and tourist areas due to their strength, lightweight nature, environmental sensitivity, and the ability to construct on challenging terrains without heavy equipment.

What are the key factors for maintaining the integrity of steel structures in extreme environments?

The key factors include load distribution through engineered truss systems, corrosion resistance via galvanized coatings, and thermal compensation using expansion joints.

How do steel structures withstand high winds and seismic activity?

Steel structures are designed to bend rather than break when stressed. This flexibility, coupled with strength, helps them endure high winds over 150 mph and distribute forces evenly during seismic activities.

What standards guide the construction of steel structures in scenic locations?

Steel structures in scenic spots adhere to the International Building Code (IBC) and may also follow standards from the American Institute of Steel Construction (AISC) for fabrication and safety.

Table of Contents

- Understanding Steel Structure Integrity in Challenging Environments

- Compliance with International and Local Steel Structure Safety Standards

- Wind, Seismic, and Extreme Weather Resistance in Steel Homes

- Material Quality and Corrosion Protection in Exposed Climates

- Foundation, Roofing, and Connection Systems for Maximum Stability

-

FAQ

- Why are steel structures used in scenic and tourist areas?

- What are the key factors for maintaining the integrity of steel structures in extreme environments?

- How do steel structures withstand high winds and seismic activity?

- What standards guide the construction of steel structures in scenic locations?