Material Durability: Selecting Weather-Resistant Cabin Components

Comparing steel, engineered wood, and composite cladding for long-term outdoor exposure

The type of cladding chosen plays a big role in how well a cabin holds up over time in tough outdoor conditions. Hot dip galvanized steel offers great protection against impacts and strong winds, lasting more than 20 years even in really harsh weather. For those looking at engineered wood options, cross laminated timber brings both green credentials and good dimensional stability through extreme temperature changes as long as all joints and openings are properly sealed against water getting in. Composite materials made from recycled wood mixed with UV stabilized plastic provide excellent defense against rotting insects and fading colors without needing regular stains or sealants applied. These composites keep looking good for around 50 years in actual field conditions. When building near coasts or places where humidity runs high, aluminum composite panels that won't corrode beat standard wood by about three times in lab tests that speed up aging processes.

Corrosion, UV degradation, and rot resistance–what truly extends cabin lifespan

The lifespan of materials really depends on their ability to handle three main challenges: corrosion from saltwater, damage from sunlight, and breakdown caused by living organisms. Take powder coated aluminum for instance. Tests done last year showed these coatings hold up against salt spray about 40% better than regular steel, which explains why boat manufacturers love using them for parts that get constantly exposed to seawater. When it comes to wood products, engineered options with built-in water resistance shrink much less when wet compared to normal lumber. We're talking around 30% less swelling, which means fewer problems with warped boards and failed joints over time. Down at ground level, composite wraps work wonders too. They keep groundwater away but still let moisture escape, something absolutely necessary to stop wood from rotting prematurely. And don't even think about skipping UV protection in areas with intense sun exposure. Regular plastic just doesn't cut it. Studies show untreated plastics break down five times quicker in mountain regions where UV levels are through the roof. That's why outdoor furniture makers insist on special stabilized polymers for their products.

Structural Integrity: Engineering for Climate Resilience and Longevity

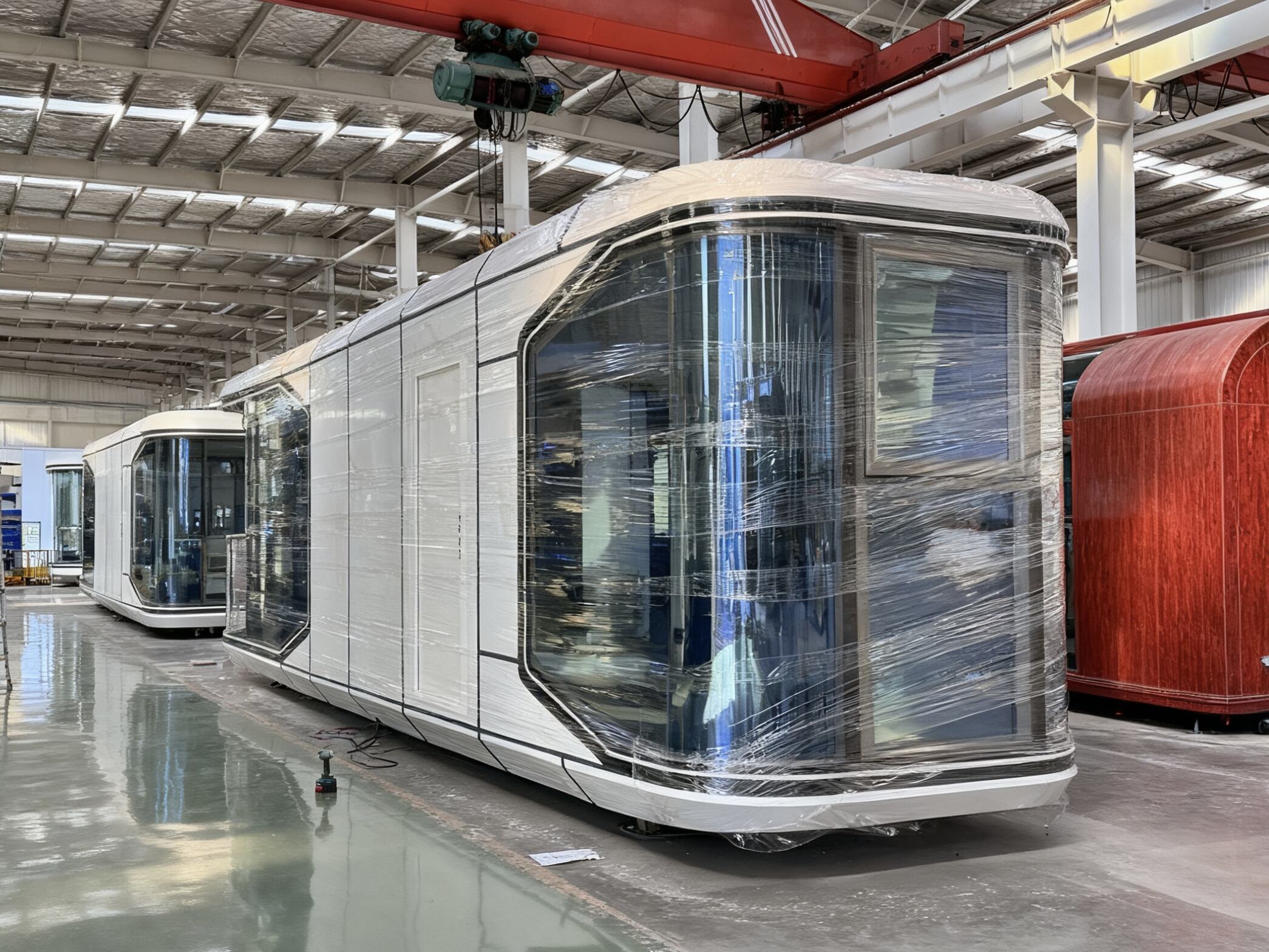

Factory precision, joint sealing, and reinforcement strategies for wind, snow, and seismic loads

Factory built modular cabins maintain better structural consistency because they're made under controlled conditions where tolerances stay within about 1/8 inch. This precision makes sure all parts fit together properly something traditional on-site construction often struggles with. For weather protection, these units use advanced sealing techniques that combine EPDM gaskets with special liquid coatings to create barriers against drafts and moisture. The result? Air leaks get reduced by over 50% compared to standard flashing approaches used in conventional buildings. Reinforcements inside include strong steel bracing hidden in walls and anchoring systems designed to hold up against winds exceeding 150 mph speeds. Frames built to withstand earthquakes meet California's strict OSHPD 3 requirements, and the roof trusses can handle weight loads of up to 70 pounds per square foot preventing problems from heavy snow buildup. Testing by independent labs shows these structures keep their strength even after going through thousands of simulated stress tests equivalent to many years of harsh weather conditions.

Roof, wall, and insulation design optimized for extreme cold, heat, and monsoon conditions

Roofs designed for monsoon conditions typically have steep slopes of at least 6:12 pitch and interlocking metal panels that can handle more than 12 inches of rain falling every hour. These panels also expand and contract safely even when temperatures reach around 110 degrees Fahrenheit. The walls incorporate steel studs with thermal breaks combined with six inches of continuous mineral wool insulation rated R-30 or better. This setup helps reduce thermal bridging so indoor temperatures stay stable even during extreme cold events where outside temps drop as low as minus 40 degrees. For buildings located in dry areas, applying reflective cool roof coatings can bounce back about 85 percent of incoming solar heat. According to recent studies from the US Department of Energy released last year, this reduces air conditioning needs by roughly 40 percent. When dealing with locations prone to flooding, raising the foundation level along with closed cell spray foam insulation (which provides about R-7 insulation value per inch thick layer) keeps moisture out while maintaining good energy efficiency even when humidity levels spike past 90 percent. Every construction assembly meets the ASTM E283 standard for water resistance under 8 pounds per square foot of wind pressure and has passed UL 263 testing requirements for fire resistance as well.

Site Integration: Foundations, Drainage, and Terrain Adaptability

Matching foundation systems (helical piles, piers, slabs) to soil, slope, and flood risk

Choosing the right foundation type needs to match the specific geology of each construction site. When there's a mismatch between foundation systems and ground conditions, about 40% of structural problems occur in hilly or unstable areas according to recent industry data from 2024. Helical piles work great when installed quickly and with minimal disruption above high water tables, which makes them particularly suitable for places prone to flooding. For sites with uneven soil strength, concrete piers can handle heavy loads and stabilize slopes effectively. Slab foundations still offer good value on solid, predictable ground, though they require thorough soil compaction and proper load testing first. Most engineers insist on detailed soil reports that check things like how water moves through the ground, how much force the soil can take before failing, and whether it might settle over time instead of guessing what the ground will do. Looking at flood risk zones specifically, using elevated pier systems cuts down on moisture damage issues by around 70% compared to regular slab foundations.

Drainage planning and elevation strategies to prevent moisture intrusion and settlement

Good drainage work should be done ahead of time, not after problems start showing up. Sloping the ground at least five degrees away from buildings cuts down on foundation pressure by around 80 percent according to what we've seen in practice. Those perimeter drains along the edges really help catch underground water before it gets too much for the soil to handle. For areas prone to flooding, raising those cabin platforms between eighteen and twenty-four inches off the ground makes all the difference. It stops water from getting inside directly and lets air circulate underneath naturally. Putting gravel under modular cabins helps spread out water quickly, which tackles the soil expansion issue that causes about a third of all settlement problems. Combine these methods with proper vapor barriers running continuously and good ventilation in crawl spaces, and there's significantly less chance of mold growing plus fewer issues with structural movement during heavy rains. Most folks report their foundations last about twenty-five years longer when they implement this kind of comprehensive system.

Low-Maintenance Cabin Design: Features That Sustain Performance Over Time

20+ year warranty cladding, self-draining decks, and corrosion-resistant fasteners

Low maintenance design really begins with parts made to last forever rather than just being easy to work with. When cladding comes with those transferable 20 plus year warranties, it basically tells us how well it stands up to things like moisture, sunlight exposure, and all that expansion contraction stuff over time. Modern self draining decks have these gentle 2 to 3 degree slopes built right in along with hidden channels that keep water from pooling around. This helps prevent problems like cracking from freezing and thawing cycles, rotting wood, and those annoying ice dams we see in colder areas. The important connection points between materials typically use either stainless steel or specially coated fasteners designed specifically to fight off galvanic corrosion which is what causes most joints to fail early when different metals are mixed together. According to tests done by major manufacturers, putting all these features together cuts down on regular maintenance needs somewhere between 60 and 75 percent compared to traditional cabin construction methods.

Balancing aesthetic finishes with proven durability in high-traffic outdoor cabin use

When it comes to lasting beauty, picking finishes based on performance matters most. Surfaces with texture and resistance to abrasion work wonders on floors, stairs, and railings where they handle constant foot traffic, moving furniture, and seasonal messes without showing wear too quickly. Nano ceramic coatings applied to decks, sidings, and trim keep their colors vibrant and glossy for over a decade, even when exposed to harsh sun conditions near coasts or mountains. Dark composite materials are great at hiding scratches and signs of weather until next cleaning day arrives. Steer clear of natural materials that need sealing twice a year since they tend to be trouble. Engineered options mimic wood grains but stand up to impacts much better than real wood does. Testing shows these materials stay looking good with just occasional washing every couple of years. No need for tedious sanding jobs, refinishes, or replacements down the road either.

Regulatory Readiness: Ensuring Your Modular Cabin Meets Code and Use Requirements

Getting around building regulations isn't something that can be skipped if we want our modular cabins to last long term. The structures need to meet all standards set by the International Building Code (IBC) plus whatever extra rules apply locally for things like how strong they are, what happens during fires, who can access them, and connecting utilities properly. Different areas have different rules which makes compliance tricky business. A design might work great in California could run into problems in New York because of differences in earthquake zones, snow weight limits, or coastal flooding maps. Making sure everything checks out happens in stages really. First comes checking what gets made in factories, then verifying before shipping, and finally inspecting after assembly on site. For rental cabins there are even more rules to follow. They need to stick to hotel style occupancy numbers, have clear escape routes in emergencies, and make sure people with disabilities can move around easily. Talking with local officials early on about these requirements saves headaches later when trying to get permits approved.

- Site-specific zoning allowances and setbacks

- Environmental review thresholds and mitigation requirements

- Utility interconnection certifications (electrical, septic, water)

Manufacturers holding multi-state factory certifications significantly accelerate permitting–reducing approval delays by 2–5 weeks on average, per 2024 industry survey data.

FAQ

What materials are best for weather-resistant cabin cladding?

Steel, engineered wood, and composite materials are ideal for weather-resistant cabin cladding due to their durability and long-term outdoor exposure capabilities.

How can modular cabins achieve climate resilience?

Precision factory building, advanced sealing techniques, and strategic reinforcements help modular cabins achieve better climate resilience and longevity.

What drainage strategies help prevent cabin foundation issues?

Proper ground sloping, perimeter drains, and raised cabin platforms significantly reduce foundation pressure and moisture intrusion issues.

How do I ensure my cabin meets regulatory requirements?

Ensuring compliance with the International Building Code and local regulations, checking at multiple stages, and consulting local officials early can help ensure your cabin meets all necessary requirements.

Table of Contents

- Material Durability: Selecting Weather-Resistant Cabin Components

- Structural Integrity: Engineering for Climate Resilience and Longevity

- Site Integration: Foundations, Drainage, and Terrain Adaptability

- Low-Maintenance Cabin Design: Features That Sustain Performance Over Time

- Regulatory Readiness: Ensuring Your Modular Cabin Meets Code and Use Requirements

- FAQ