Rapid Deployment: How Container Offices Accelerate Project Mobilization

Pre-Fabricated Integration: Electrical, Data, and Anchoring Systems Ready for Immediate Use

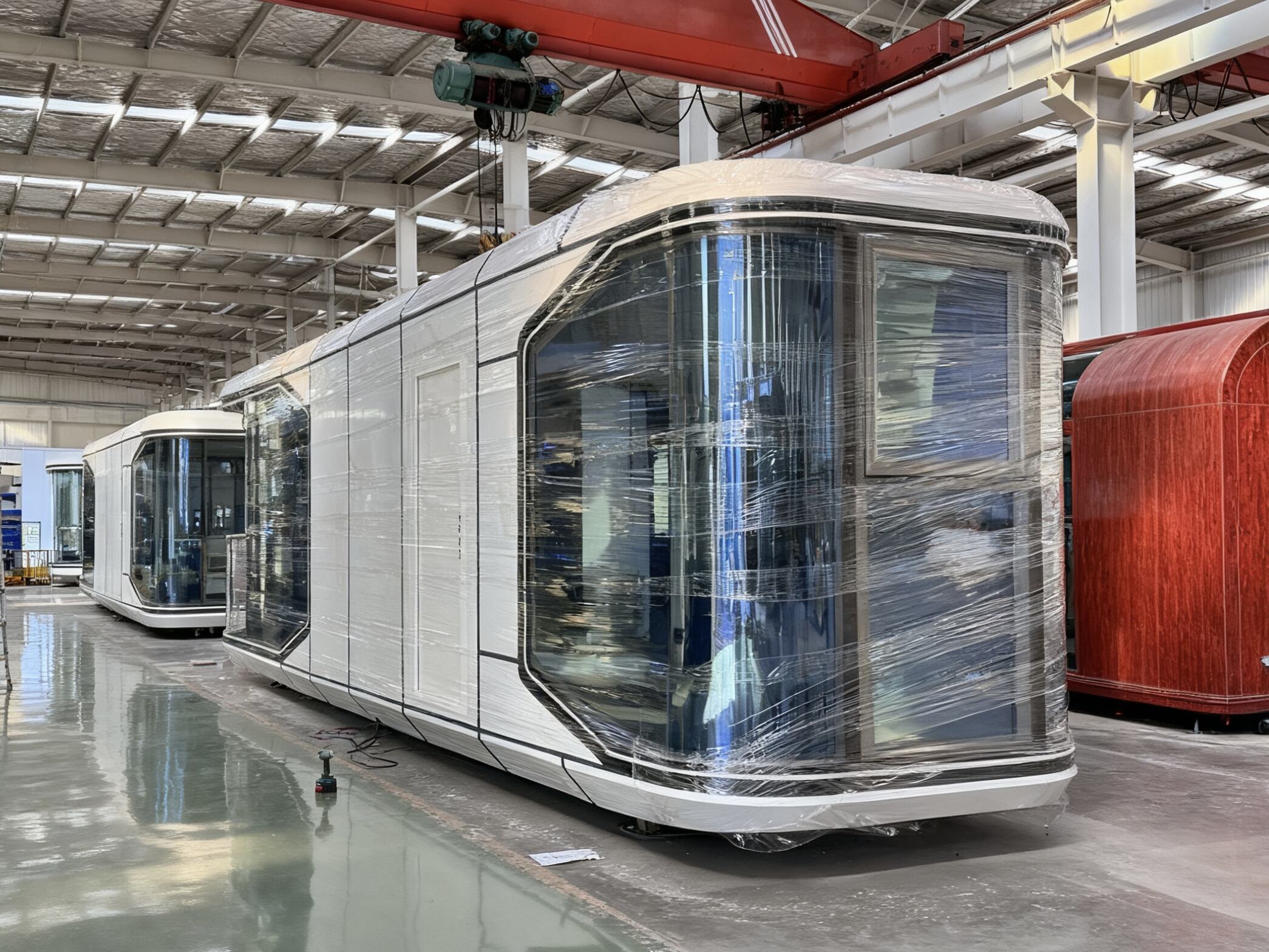

Container offices speed up getting projects going because everything important is already made before they arrive on site. Traditional site cabins need lots of separate work done at the location first like running electricity, laying cables, and building foundations. But these ISO certified containers come ready to go with proper wiring that meets NEC standards, organized Cat6 data lines, and special anchor points that have been checked and tested ahead of time. All a contractor needs to do is put the unit where it goes, hook up to whatever power and water sources are already there through those convenient access panels, then flip switches and start using them right away usually in just a few hours instead of waiting weeks. This all-in-one package saves contractors around two to three weeks of back and forth between electricians, IT folks, and construction workers. The military style anchors come pre-tested for different types of ground conditions so no one has to spend extra time doing soil tests. Plus with lighting that follows OSHA rules, complete ductwork for heating and cooling, and internet ports ready to plug into, these office containers are basically ready for business as soon as they roll off the truck.

Case Study: 68% Faster Site Activation on a Dallas High-Rise Using ISO-Certified Container Offices

The Dallas high-rise project moved at lightning speed when they swapped out regular site cabins for ISO certified container offices. With tight deadlines looming, the contractor brought in ready-to-use containers complete with electrical panels already wired, generators that cut down vibrations, and built-in Cat6 network connections. Setting up traditional office spaces usually takes around 37 days, but these containers were fully functional within 12 days once everything was in place including climate controlled desks, secure data systems, and safety equipment ready for inspections. The ISO 9001 certification meant all compliance papers came packed with each container, saving those extra 14 days contractors normally spend checking field installed systems. Looking back after completion, it turned out this fast setup knocked three whole weeks off their timeline, proving container offices can really help push projects forward when time is money.

Cost Efficiency: Total Ownership Advantages of Container Office Units

TCO Comparison: 35–50% Lower Over 18 Months vs. Traditional Site Cabins

Container offices deliver 35–50% lower total cost of ownership (TCO) over 18 months compared to traditional site cabins, driven by efficiencies across four core expense categories:

| Cost Factor | Traditional Site Cabins | Container Offices |

|---|---|---|

| Installation | Weeks of labor | Pre-assembled modules |

| Maintenance | Frequent repairs needed | Corten steel durability |

| Relocation | Demolition/rebuild costs | Modular reconfiguration |

| Energy Consumption | Poor insulation penalties | R-22+ thermal efficiency |

Standardized manufacturing cuts setup labor by 60%, while corrosion-resistant Corten steel reduces annual maintenance expenses by 47% (Construction Economics Review, 2024). These structural and process advantages compound over time—making container offices not just faster to deploy, but demonstrably more economical across their operational lifecycle.

Avoiding Hidden Costs: Evaluating Soft Expenses in Low-Cost vs. Integrated Container Office Providers

Many budget container office suppliers hide real money problems that proper engineering solutions actually avoid. Cheaper units usually don't get tested properly which causes all sorts of issues down the road. Offices lose productivity because they can't control temperatures well enough. There's also big compliance risks when wind gets strong since the anchors aren't certified for those conditions. Moving these cheap containers takes forever too, about two to three days just to retrofit them for each new location. And let's not forget about safety concerns with access points that don't meet OSHA standards. Looking at actual project data across multiple sites, these hidden costs pile up somewhere between $115k and $220k over the whole project life. That's why companies going for premium integrated solutions end up saving money in the long run even though they pay more initially. These better quality units come with built-in compliance features, weather resistance, and designs that actually work with normal business workflows instead of fighting against them.

Durability, Security, and Compliance: Engineering Container Offices for Active Sites

Material & Structural Standards: Corten Steel, 130-MPH Wind Load, and UL 1037 Forced-Entry Resistance

Container offices designed for busy construction sites are built to last through tough conditions. They're constructed primarily from Corten steel, which is specially made to resist rusting even after years of exposure. This makes them suitable for placement near the ocean, out in deserts, or right next to factories where regular steel would quickly deteriorate. When it comes to standing up to Mother Nature, these containers have been tested thoroughly. Wind load tests show they can handle winds blowing at around 130 miles per hour without toppling over. Security isn't overlooked either. The doors meet UL 1037 standards for resisting forced entry attempts. What does this mean practically? Reinforced frames around the doors, locks that engage at multiple points when closed, and hardware that won't give way easily if someone tries to tamper with it. All these design elements work together so workers can count on having a safe, sturdy office space no matter what kind of abuse or weather comes their way during a project.

Workflow-Optimized Customization and Climate-Adaptive Comfort in Container Offices

Modular Interior Layouts: Multi-Zone Configurations (Admin, Tech Hub, Quiet Room) and Tool-Free Reconfiguration

Container offices really help with changing project needs because of their smart, modular interior setups. The sliding walls and furniture that just click into place let teams rearrange different areas fast. We're talking administrative spaces for managers, tech corners where engineers work on CAD stuff, and soundproofed spots for people who need to concentrate all done in about four hours flat and no tools needed. When projects change direction halfway through, this kind of setup saves tons of time instead of waiting for construction crews. Separating these zones also cuts down on distractions between activities. Imagine trying to review blueprints while someone is shouting over field updates next door. Site supervisors love being able to switch spaces as needed too. A staging area becomes a safety meeting room one day, then turns into a prep zone for materials the next. Keeps everything moving smoothly even when things get chaotic.

Smart HVAC and Advanced Insulation: Meeting OSHA Heat-Stress Requirements with R-22+ Thermal Performance

Container offices keep workers comfortable and productive thanks to climate control systems designed to meet safety regulations while actually working in practice. Many modern container setups use ductless mini-split HVAC units with built-in occupancy sensors. These sensors automatically adjust how much cooling gets delivered depending on whether people are actually in the space. The result? Temperatures inside typically remain under OSHA's 77 degree Fahrenheit limit for heat stress. What makes this possible? The walls are often insulated with R-22+ closed cell spray foam. This stuff offers about 43 percent better thermal resistance compared to regular fiberglass insulation. Plus it stops moisture from getting in, which helps maintain good air quality over time. During those brutal summer months when temperatures outside skyrocket, these systems help avoid worker slowdowns caused by heat exhaustion. At the same time they cut down on electricity bills because the compressors only run when needed. Most users find the balance between comfort and efficiency works pretty well in day to day operations.

Sustainability and Scalability: The Lifecycle Value of Repurposed Container Offices

Environmental Impact: 76% Lower Embodied Carbon and 2.5-Ton Steel Diversion per 20-Foot Unit

Turning old shipping containers into temporary offices on construction sites actually helps the environment quite a bit. When someone reuses a standard 20 foot container, they keep about 2.5 tons of steel out of landfills instead of melting it down again. The carbon footprint drops around 75% too when compared to building brand new portable offices from scratch. Contractors who go this route cut back on needing fresh raw materials, skip pouring concrete foundations, don't need wooden frames, and basically eliminate all that waste from tearing things down later. Most green building experts agree these methods fit right in with what the world is trying to accomplish regarding carbon reduction goals. Take the World Green Building Council's plan for net zero emissions by 2030 as an example. For companies looking ahead, investing in container offices makes sense both environmentally and economically, especially as regulations get stricter and clients demand greener solutions.

Phased Growth & Relocation: 'Grow-as-You-Go' Clusters for Linear Infrastructure Projects

For linear infrastructure projects such as pipelines, rail lines, and road expansions, container offices offer a flexible solution that grows with the job site needs. These containers come in standard sizes and have built-in anchoring features so construction teams can get basic office space set up in just under two days. As the project moves forward, additional containers can be added bit by bit without having to spend money on extra space nobody will use. According to research published in Civil Engineering Journal last year, this approach cuts down on wasted capacity costs somewhere between 30% and maybe even 45%. When the work wraps up, these office containers aren't thrown away either. They simply move to another location where they keep most of their value since they don't need tearing apart. This reuse factor means companies save money over time and help reduce construction waste at the same time.

FAQs

What are the main advantages of using container offices over traditional site cabins?

Container offices are pre-fabricated with electrical, data, and anchoring systems, allowing rapid setup and reducing the need for separate site work. They are cost-efficient, durable, environmentally friendly, and adaptable to changing project needs.

How much time can be saved using container offices?

Container offices can be fully functional within just a few hours, compared to several weeks for traditional site cabins, saving up to three weeks in project timelines.

Are container offices environmentally sustainable?

Yes, converting shipping containers into office spaces significantly lowers carbon footprint and reduces steel wastage, aligning with global carbon reduction goals.

Table of Contents

- Rapid Deployment: How Container Offices Accelerate Project Mobilization

- Cost Efficiency: Total Ownership Advantages of Container Office Units

- Durability, Security, and Compliance: Engineering Container Offices for Active Sites

- Workflow-Optimized Customization and Climate-Adaptive Comfort in Container Offices

- Sustainability and Scalability: The Lifecycle Value of Repurposed Container Offices

- FAQs