Understanding the Lifespan and Core Durability Factors of Mobile Houses

The lifespan of a mobile house typically ranges from 30 to 55 years, influenced by construction quality, climate resilience, and maintenance. Industry research (2023) identifies three key determinants: structural design, material selection, and environmental exposure.

What Determines the Lifespan of a Mobile House?

Structural integrity begins with compliance to HUD standards, which require wind resistance up to 110 mph and frost-protected foundations. Roofing materials like galvanized steel and adequate wall insulation thickness are critical for weatherproofing performance. Proper installation and ongoing upkeep further ensure long-term durability.

Average Service Life Based on Construction Standards

| Construction Type | Average Lifespan | Cost Range | Value Trend |

|---|---|---|---|

| Mobile (HUD-Compliant) | 30–55 years | $36k–$84k | Depreciates 1–2%/yr |

| Modular (Site-Assembled) | 40–70 years | $80k–$160k | Stable with upkeep |

| Traditional Site-Built | 50–100+ years | $250k–$500k | Appreciates 3–5%/yr |

How Climate Impacts the Longevity of Mobile Houses

Coastal regions accelerate corrosion in untreated steel frames by 30% compared to arid climates. In snowy areas, roofs rated below 35 psf face a 40% higher risk of structural failure (Northern Climate Institute 2023). Design features such as thermal expansion gaps in siding and UV-resistant window coatings help mitigate climate-induced wear.

Comparative Analysis: Mobile vs. Modular vs. Traditional Site-Built Homes

Mobile homes offer cost-efficiency and relocation flexibility, while modular units balance durability with semi-custom designs. Traditional homes provide superior longevity but require five times the upfront investment. For temporary or rotational use—such as camping sites—mobile houses deliver optimal cost-to-durability ratios when maintained annually.

Key Materials That Enhance Durability in Mobile House Construction

Key Materials Used in Durable Mobile Home Construction

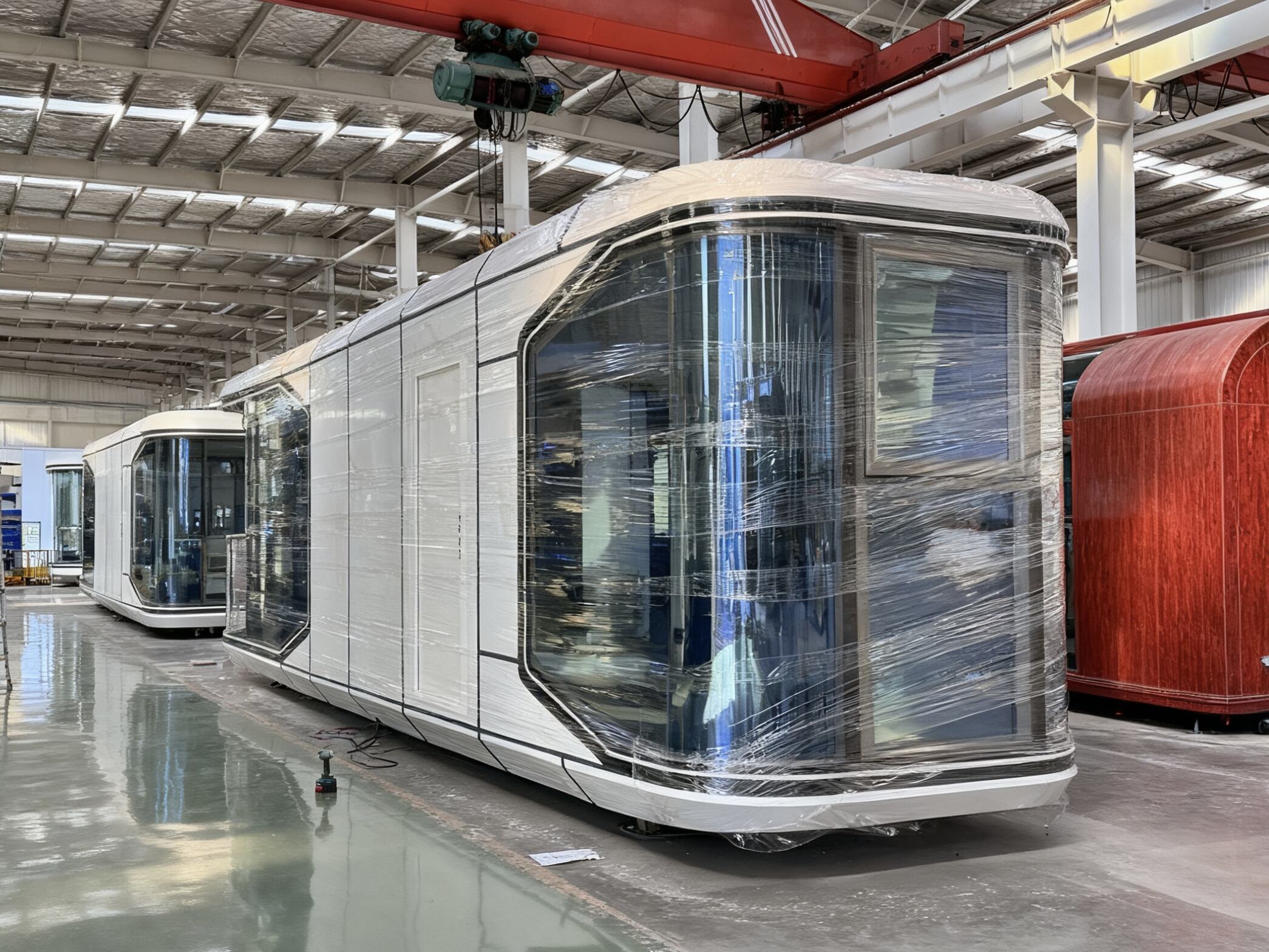

Today's manufactured housing relies on specially designed materials that can handle both the rigors of transport and whatever Mother Nature throws at them. Most factory built homes actually sit on steel frames these days, about 78 percent according to the National Fire Protection Association report from 2023. The reason? Steel offers incredible strength while keeping weight down. For those nicer model homes, builders are switching from old school vinyl exteriors to aluminum cladding instead. This new material stands up to impacts three times better than what used to be standard. And let's not forget about those fancy sealants and composite decks that manufacturers slap on nowadays. These features really cut down on water getting into places it shouldn't, which is probably why so many mobile homes last longer than people expect before needing major repairs.

Advantages of Steel Frames and Aluminum Cladding

Steel framing provides 40% greater wind-load resistance than wood, making it ideal for frequently relocated homes. Aluminum exterior panels demonstrate 99% corrosion resistance in salt-spray tests (ASTM B117), outperforming vinyl in coastal environments. Together, these materials lower average annual maintenance costs by $180 compared to conventional construction (HUD 2022).

Insulation Choices That Enhance Weather Resistance

In high end construction projects, closed cell spray foam has become pretty much standard these days. It gets about R 6.5 per inch rating while creating that tight seal against air and moisture. For buildings located where flooding is a real concern, putting rigid foam under floors cuts down on ground moisture getting inside by roughly 92 percent according to industry data. And there's something new coming onto the market too aerogel infused mats that pack an impressive R 13 value but take up only half the space compared to regular fiberglass batts. This makes them especially useful for small spaces like RVs or tiny homes where every square inch counts.

Sustainable and Corrosion-Resistant Material Innovations

Many manufacturers are now able to use as much as 90 percent recycled steel in their structural parts and still maintain good tensile strength. The color on these structures stays vibrant too thanks to UV stabilized polymer composites that keep looking fresh for around 25 years or so. That actually solves one of the biggest problems found during inspections of mobile homes where faded exteriors were always an issue. For places with really hot weather, ceramic based thermal coatings work wonders. They can drop indoor temps by about 15 degrees Fahrenheit even when it's scorching outside. Plus these coatings stand up well against sand and dust wear, which makes them particularly useful for installations in dry regions where such damage would normally be a big concern.

Engineering for Environmental Resilience: Design and Structural Integrity

Engineering Principles Behind Stable Mobile House Frameworks

Durable mobile homes rely on engineered frameworks that efficiently distribute loads. Steel-reinforced floor systems and interlocking wall panels create unified load paths, while roof trusses with 2:12 to 4:12 slopes effectively shed precipitation. Cross-bracing in critical zones minimizes lateral movement during transport, preserving structural integrity across multiple relocations.

Wind, Snow, and Seismic Load Considerations

Homes constructed in areas where hurricanes hit regularly can handle wind speeds between 110 and 130 miles per hour thanks to their special aerodynamic shapes and those hurricane straps that really secure the walls down to the foundation. When it comes to roofs, they're designed to support snow loads ranging from 40 to 70 pounds per square foot. These structures have extra strong trusses placed every 16 inches apart for added strength. For buildings located in earthquake-prone regions with ground accelerations as high as 0.4g on the design scale, base isolation systems make a big difference. These systems cut down how much shaking gets transferred from the ground into the building itself by somewhere around 60 to 80 percent when compared to traditional fixed foundations.

Foundation Systems for Enhanced Structural Integrity

Four foundation types extend mobile house longevity:

- Helical piers (ideal for floodplains, 10–20 ton capacity)

- Reinforced concrete slabs with vapor barriers (humidity control)

- Perimeter masonry walls with adjustable steel piers (slope stability)

- Geotextile-enhanced gravel pads (drainage optimization)

When properly installed, these systems limit settling to ¼1/4" per decade.

Case Study: Mobile Houses Surviving Extreme Weather Events

During 2023's Cyclone Gabrielle, 83% of engineered mobile houses in New Zealand’s Hawke’s Bay region remained intact despite 145 mph winds and 12" rainfalls—outperforming 34% of conventional homes. Key survival factors included:

- Continuous steel chassis underpinning

- Impact-resistant laminated glass (ASTM E1996 Level D certified)

- Elevated foundations with 18" flood clearance

This highlights how purpose-built engineering can exceed traditional housing resilience in extreme conditions.

Climate-Specific Performance and Protective Features

Performance in Humid, Arid, and Cold Climates

Durability issues really stand out when mobile homes are placed in different climate zones. Take humid areas first where moisture is always a concern. Using aluminum siding along with stainless steel hardware cuts down on rust problems quite a bit according to recent studies from Ponemon back in 2023, though they mention around 60 something percent improvement. Desert locations present their own set of challenges too. The roofs made from special polymer materials that resist UV damage actually bounce back most of the sun's heat, which keeps them from getting too brittle over time. And then there are those freezing conditions where triple pane windows filled with argon gas become essential. These windows keep things comfortable inside even when temperatures drop below minus forty degrees Fahrenheit without putting too much strain on the window frames themselves.

UV Protection and Thermal Expansion Management

Ceramic-coated roofing and expanded thermoplastic wall panels address two major issues:

- UV degradation resistance extends from 10 to 25 years

- Thermal expansion tolerance improves by 40% versus traditional vinyl siding

According to the 2023 Material Flexibility Study, these innovations reduce weather-related repair costs by $17,500 over 15 years.

Moisture Control and Mold Prevention Strategies

When advanced ventilation systems work together with closed cell spray foam insulation, they form a moisture barrier that outperforms traditional fiberglass batts by around eight times. This makes a huge difference in preventing water damage issues. For floors in areas prone to dampness, anti microbial underlayments have shown remarkable results too. Testing in high humidity conditions revealed these materials reduce mold spore growth by nearly 90%, which is pretty impressive for anyone dealing with moisture problems. Coastal properties need special attention because of salt air exposure. That's why many builders now specify galvanized steel frames with zinc nickel plating for their coastal projects. These components last approximately three times longer against salt spray corrosion compared to regular powder coated alternatives, making them a smart investment for beachfront construction where equipment longevity matters most.

Maintenance and Transport: Ensuring Long-Term Durability of Mobile Houses

Durability Challenges During Transportation of Mobile Homes

Transport exposes mobile homes to structural stress, vibration, and weather risks that compromise longevity. Studies indicate 40% of premature wear stems from transit damage (Ponemon 2023). Primary vulnerabilities include:

- Frame flexure: Repeated movement weakens joint integrity

- Material fatigue: Roofing and siding endure erosion at highway speeds

- Moisture intrusion: Poor weatherproofing during moves accelerates corrosion

Reinforced undercarriages, vibration dampeners, and temporary sealants help manufacturers mitigate these risks. Units moved more than three times typically require 18% higher lifetime maintenance than permanently sited models.

Routine Maintenance to Extend the Life of a Mobile House

Proactive maintenance reduces repair costs by 60% and can extend lifespans beyond 55 years (Manufactured Housing Institute 2023). Essential tasks include:

| Maintenance Area | Frequency | Key Actions |

|---|---|---|

| Roof & Sealants | Biannually | Inspect seams, replace cracked caulk |

| Structural Anchors | Annually | Tighten fasteners, check corrosion |

| Climate Systems | Quarterly | Clean HVAC filters, inspect ductwork |

Weekly gutter cleaning prevents water pooling, while monthly skirting inspections deter pests. In coastal areas, installing sacrificial anodes on steel frames reduces saltwater corrosion by 73%.

FAQ

How long do mobile houses typically last?

Mobile houses generally last between 30 to 55 years, depending on construction quality, maintenance, and environmental factors.

What materials are best for enhancing the durability of mobile houses?

Steel frames and aluminum cladding are highly effective, offering significant resistance to wind and corrosion, especially in harsh conditions.

How does climate affect the lifespan of mobile houses?

Different climates pose unique challenges. For instance, coastal areas can accelerate corrosion, while snowy areas might lead to structural failures if roofs are not rated for heavy snow loads.

Can regular maintenance extend the life of a mobile house?

Yes, proactive maintenance can significantly extend the life of a mobile house and reduce repair costs.

What are the transportation challenges for mobile houses?

Transporting mobile houses can expose them to structural stress and weather risks, leading to increased wear and tear.

Table of Contents

- Understanding the Lifespan and Core Durability Factors of Mobile Houses

- Key Materials That Enhance Durability in Mobile House Construction

- Engineering for Environmental Resilience: Design and Structural Integrity

- Climate-Specific Performance and Protective Features

- Maintenance and Transport: Ensuring Long-Term Durability of Mobile Houses

- FAQ