Understanding Mobile House Vulnerability in Hurricane-Prone Areas

Why Traditional Mobile Homes Fail in Wind Zone III Conditions

Mobile homes just aren't built to handle Wind Zone III conditions where sustained winds hit 110 mph or more. Their lightweight frames, limited bracing systems, and broken load paths make them structurally weak against such forces. Site built houses typically have those engineered connections running all the way from the roof down to the foundation, something most mobile homes simply don't possess. Without these connections, mobile homes suffer from serious vulnerabilities during storms. They tend to lift off their foundations and rack sideways, particularly noticeable around window and door openings. When strong winds blow, rain gets forced into any gaps or cracks that weren't properly sealed during construction, which leads to rust problems and wood rot over time. The HUD did update building codes back in 1994 and again in 2000, which definitely raised the bar for basic safety requirements. However, plenty of older models still sitting out there, along with newer ones that weren't anchored correctly when installed, remain at risk during Category 2 hurricanes and above.

HUD Wind Zone Certifications vs. Real-World Storm Performance

HUD certifications set basic standards for how well buildings resist wind, but lab tests just can't match what happens in actual hurricanes. Real storms bring all sorts of complications that labs miss completely: swirling winds coming from different directions, sudden changes in air pressure, and the mess when rain mixes with high winds. What's really important to note here is that these certifications rely on perfect installations using special anchoring systems, something that rarely happens in real life. After major storms, both FEMA and IBHS have found time and again that even certified structures start failing when winds hit around 20 to 30 miles per hour less than what they were supposed to handle. This shows there's a big difference between how things perform in controlled environments versus what actually happens when a storm makes landfall.

FEMA Data on Mobile Home Destruction Rates in Category 2+ Hurricanes

According to FEMA's 2023 Coastal Damage Assessment Report, there's something really interesting going on with mobile homes along the coast. These structures make up under 10% of all coastal housing but somehow end up being responsible for almost 40% of the damage when hurricanes hit. Older mobile homes built before 1994 are especially vulnerable, with about 90% getting completely destroyed when they're directly hit by Category 3 storms. That's a huge jump from newer models constructed after 2000 which only see around 35% destruction rates. Looking at what actually breaks down during these events gives us some clues about where to focus improvements. The main problems tend to be roofs pulling away from walls once wind speeds pass 90 mph, anchors coming loose from their mounting points, and gradual weakening caused by water intrusion over time. Strengthening these specific areas seems to offer the most bang for our buck in terms of making these homes withstand future storms better.

Key Design Features of a Hurricane-Resistant Mobile Home

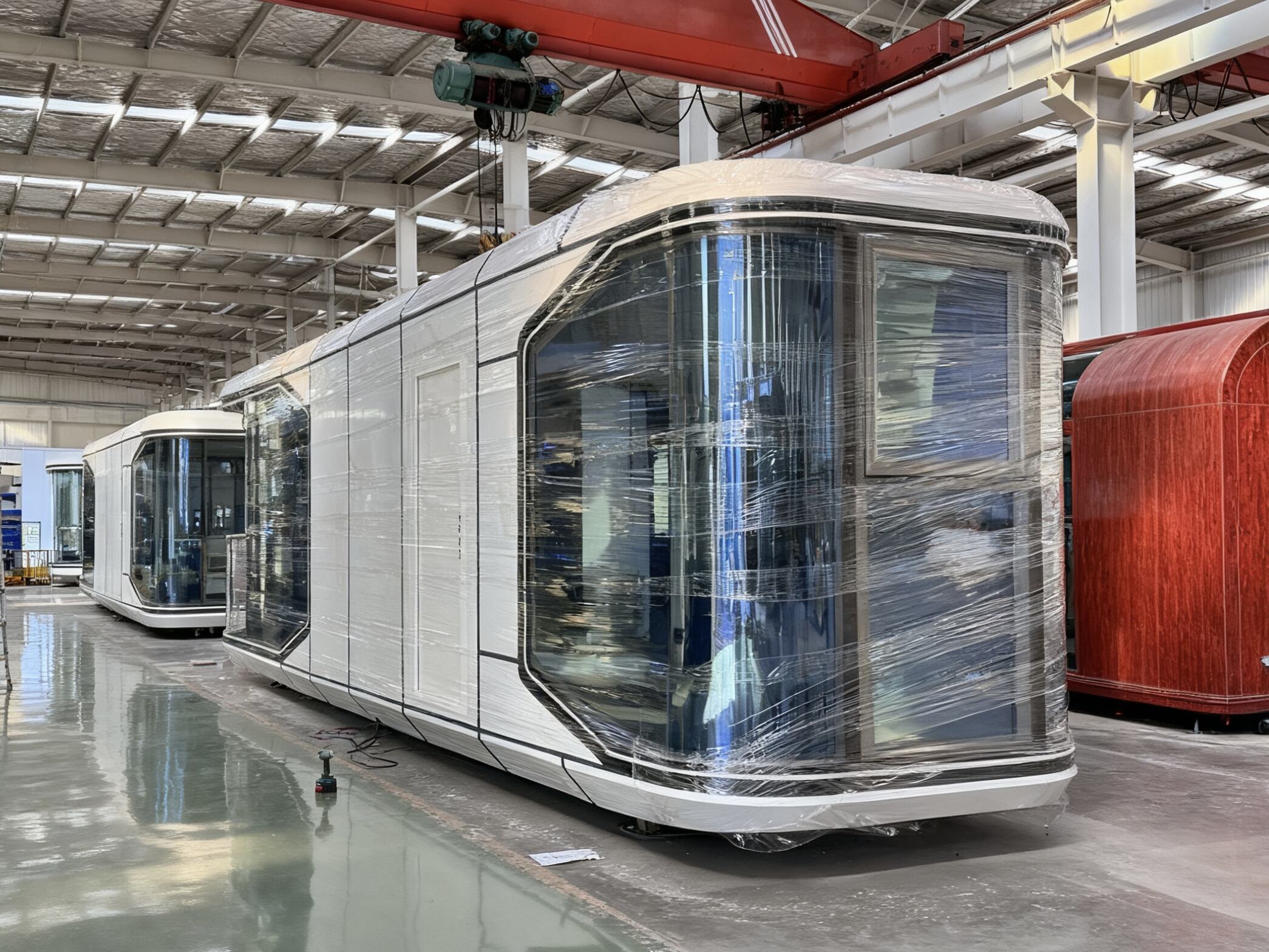

A hurricane-resistant mobile home goes beyond code-minimum compliance by integrating tested, interdependent systems: impact-rated laminated windows, steel-reinforced framing with hurricane clips, and continuous load paths that channel wind forces safely to the ground.

Elevated Foundations and Integrated Flood Protection

Elevation on pilings or reinforced slab-on-grade foundations lifts habitable space above 100-year flood levels while protecting mechanical systems. Integrated utility chases and sealed conduit entries prevent storm surge infiltration—critical since water damage accounts for over 40% of total hurricane losses in elevated coastal zones.

Sealed Sheathing and Advanced Weatherproofing for Wind-Driven Rain

Continuous, taped sheathing—paired with fluid-applied or self-adhered weather-resistive barriers—creates a true secondary drainage plane. This system stops wind-driven rain before it reaches framing, eliminating the chronic moisture intrusion that compromises insulation, fasteners, and structural integrity in conventional installations.

Roof, Siding, and Sealing Integrity Under 130+ mph Winds

Hip roofs with four slopes cut down on wind uplift by around 40 percent compared to traditional gable roofs, especially when builders install those hurricane straps that connect the roof to wall studs and the foundation below. For exterior protection, impact resistant metal siding works wonders too. When installed properly with hidden fasteners and completely sealed edges, this kind of siding keeps the building envelope intact during long periods of Category 4 winds, which blow between 130 and 156 miles per hour. The sealing prevents small holes or damage spots from turning into bigger problems that spread through the whole structure.

Anchoring and Structural Reinforcement for Outdoor Resilience

Tie-Down Systems and Hurricane Clips: Engineering Stability in High Winds

Wind resistance starts right beneath our feet. The foundation really matters when it comes to engineered tie downs like steel straps, auger anchors, or those helical piers we see so often. These components need to create what engineers call a continuous load path all the way down from the roof deck into solid soil layers below. Installers following ICC-600 standards along with HUD's 24 CFR Part 3280 guidelines can actually cut down on structural failures caused by strong winds by over half according to testing data. For buildings near coastlines where salt air eats away at metals and freezing temperatures cause problems, using corrosion resistant materials becomes absolutely essential. Getting the anchor points deep enough below the frost line isn't optional either in these areas, it's just part of doing things right for long term durability.

Foundation Solutions for Unpaved or Remote Outdoor Sites

Traditional concrete slabs just don't work well on sandy ground or in areas that aren't developed yet. That's where ground screw anchors and those helical piers come in handy. They stabilize things pretty quickly too, each one holding over 4,500 pounds before pulling out. Best part? No need for big machinery or waiting around for concrete to cure. These modular foundation kits are basically ready to go straight from the box. They keep everything aligned properly along the load path and make it much easier when inspectors come by. Makes sense why contractors love using them in remote spots where keeping track of quality can be a real headache sometimes.

From Retrofit to Purpose-Built: Evaluating Long-Term Viability and ROI

Cost vs. Lifespan ROI: Hurricane-Resistant Modifications for Mobile Homes

Upgrading older buildings with Wind Zone III rated anchors, impact resistant windows, and sealed building envelopes usually runs around $25 to 40 thousand dollars upfront. But these improvements can stretch the lifespan of structures in hurricane zones to anywhere between 7 and 12 years, which means no need to completely rebuild after just one big storm hits. When looking at the bigger picture, it makes sense financially too. Rebuilding from scratch costs about $125k on average, plus there's the monthly expense of finding temporary accommodations during repairs at roughly $2,800 per month. And don't forget insurance companies often cut premiums by around 32% for properly fortified properties. Most people find their investment pays off within 3 to 5 years, especially if they qualify for those FEMA grants meant to help with disaster preparedness.

The Certification Gap: Why Many 'Hurricane-Resistant' Mobile Homes Lack Wind Zone III Compliance

Too many marketing promises get ahead of actual testing results. Just look at wind zone standards set by HUD - barely 19 percent pass their toughest Wind Zone III tests which simulate winds over 150 mph. Most problems start right at the base. Around 85% of all failures come down to poor connections between foundations and structures. There's also the issue with how roofs attach to walls, which varies too much across installations. And let's not forget about those materials being used as substitutes without proper vetting. Real compliance isn't about what manufacturers claim on paper. It takes independent checks of how forces travel through buildings and whether anchors hold up under stress. Self certification from companies simply doesn't cut it when lives are literally hanging in the balance during storms.

| Retrofit Type | Wind Compliance Rate | Avg. Cost Increase | Claim Reduction Potential |

|---|---|---|---|

| Full Structural | 89% certified | +27% | 61% lower |

| Partial Reinforcement | 43% certified | +14% | 22% lower |

| Cosmetic Only | 7% certified | +5% | 3% lower |

| Purpose-built units designed from inception for Wind Zone III—not retrofitted after the fact—deliver the highest reliability, lowest long-term cost, and strongest alignment with FEMA’s Hazard Mitigation Grant Program (HMGP) eligibility criteria. |

FAQ

What is a Wind Zone III condition?

Wind Zone III conditions refer to areas where sustained wind speeds can reach 110 mph or more. These are high-risk zones for hurricanes and strong wind events.

How are newer mobile homes different from older models in terms of storm resilience?

Newer mobile homes, especially those built after 2000, incorporate updated building codes, including better anchoring systems and structural reinforcements. Older models often lack these improvements, making them more vulnerable to storm damage.

What are some ways to improve the storm resilience of a mobile home?

Some effective ways to improve storm resilience include installing impact-resistant windows, reinforcing frames with hurricane clips, ensuring continuous load paths, and elevating the structure to protect against flooding.

Why do some 'hurricane-resistant' mobile homes fail Wind Zone III compliance?

Many 'hurricane-resistant' mobile homes fail Wind Zone III compliance due to poor foundation connections, varying roof-to-wall attachment methods, and the use of substandard materials not properly tested for high wind speeds.