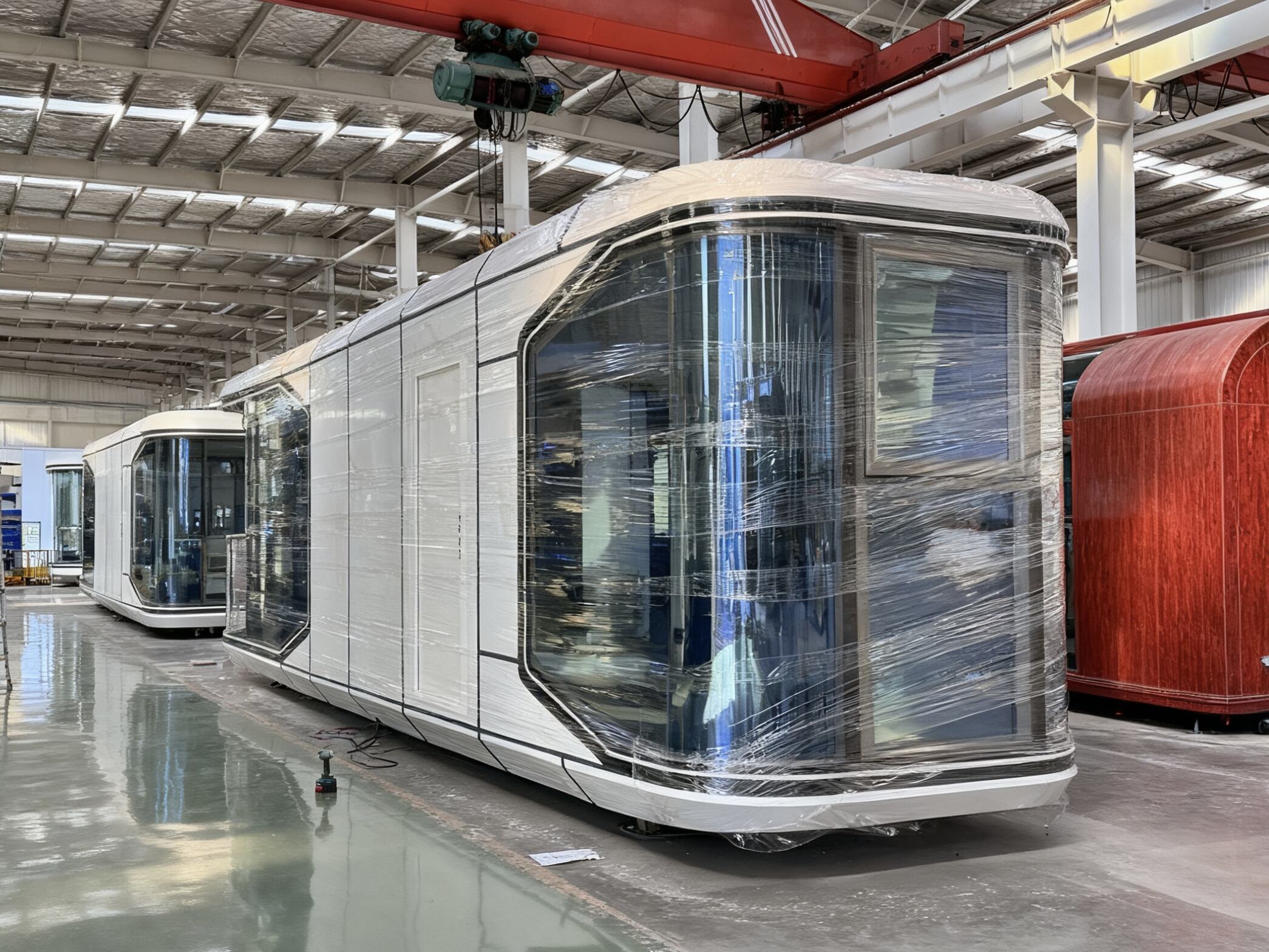

Climate-Resilient Design: Engineering Durability for Scenic Environments

Weather-Specific Structural Compliance: Mountains, Coasts, Deserts, Islands, and Forests

When building prefab homes in beautiful but challenging landscapes, engineers have to think carefully about local weather dangers. For example, houses near the ocean need special steel frames that won't rust when exposed to salty air. Out in the desert, builders install reflective coatings on walls to keep interiors cooler during those scorching days. Up in the mountains or deep within forests, extra strong roof structures are necessary not just for heavy snow but also to protect against branches falling from trees. On islands where flooding is always a concern, raising the foundation above ground level makes all the difference. And then there's wildfire country - whether it's dry brushlands, pine forests, or anywhere else prone to flames - using materials that won't catch fire becomes absolutely essential. Fiber cement siding and stone exteriors work great here. According to research from construction experts, these climate-specific design choices actually make buildings last about twice as long as standard ones built without such considerations.

Advanced Building Systems: Structural Insulated Panels (SIPs) and Airtight, Storm-Resistant Assemblies

SIPs, or Structural Insulated Panels, create buildings that are naturally sealed against air leaks, cutting down on moisture problems by around 80% in areas where humidity is an issue. These panels have great insulating properties because they combine continuous insulation with specially designed wood frames. They can actually stand up to wind speeds over 150 mph, which makes them really important for places along coasts or islands that get hit by hurricanes or typhoons regularly. Builders often pair SIPs with special windows rated for impacts and hidden fastening systems so the whole structure stays intact even when weather gets brutal. Another benefit worth mentioning is how these panels reduce what's called thermal bridging, leading to about 30% less energy needed throughout the year. That becomes especially valuable in remote locations where electricity supply might be inconsistent or just not available at all.

Material Intelligence: Sustainable, Local, and High-Performance Choices for Prefab Homes

Region-Appropriate Materials: Cedar, Thermally Modified Wood, Bamboo, and Stone in Moisture- or Fire-Prone Zones

Material selection must align with local environmental stressors—not just sustainability goals. Locally sourced options reduce embodied carbon while ensuring proven performance under regional conditions: humidity, wildfire exposure, seismic activity, or freeze-thaw cycles.

- Cedar: Naturally resistant to decay and insects—ideal for coastal and rainforest settings

- Thermally Modified Wood: Heat-treated for dimensional stability across variable moisture conditions, from arid deserts to humid lowlands

- Bamboo: Rapidly renewable (harvestable in 1–5 years) with exceptional tensile strength—well-suited for floodplains and seismically active terrain

- Stone: Non-combustible, high-mass material offering passive fire defense and thermal regulation in wildfire-prone chaparral and mountain zones

| Material | Best Climate Match | Key Resilience Attribute |

|---|---|---|

| Cedar | Coastal/Humid | Natural decay resistance |

| Thermally Modified Wood | Variable moisture | Dimensional stability |

| Bamboo | Tropical/Seismic | Rapid regeneration (1–5 years) |

| Stone | Fire-prone | Non-combustible thermal mass |

These choices reflect a shift from standardized specifications to context-driven material intelligence—extending service life, cutting long-term maintenance, and preserving ecological integrity.

Lifecycle Value: Why Upfront Investment in Durable Prefab Home Systems Pays Off Long-Term

Steel Framing, Fire-Resistant Cladding, and Reduced Maintenance: Lowering 20-Year Total Cost of Ownership

Putting more money into durable prefab systems pays off financially down the road. Steel frames just don't rot or warp like wood does, and they stand up against termites that plague many beautiful locations. This means fixing structural problems costs around 40% less over twenty years compared to traditional materials. When builders add fire rated cladding options like fiber cement panels or mineral boards, homeowners often see reduced insurance rates in areas prone to wildfires. The real advantage comes from how little maintenance these structures need. Steel doesn't expand or contract much in humid coastal climates, while modern cladding materials handle sun damage better and naturally shake off dirt and grime without needing cleaning. Studies show maintenance bills stay about 30% below average for regular construction methods, which matters a lot when repairs require bringing workers and equipment to distant sites. For those investing in property away from cities, the extra spending at the start usually turns into actual savings somewhere between ten and fifteen years later.

Builder Selection and Site Integration: Ensuring Real-World Performance in Remote Scenic Locations

Proven Regional Expertise: How Specialized Builders Navigate Colorado Desert, Pacific Northwest, Florida Hurricane, and Nordic Mountain Conditions

Regional expertise isn't optional—it's foundational to real-world durability. Builders with deep experience in specific climatic zones apply lessons refined through decades of on-site testing and adaptation.

- In Florida’s hurricane corridors, specialists engineer elevated foundations, storm-resistant wall assemblies, and erosion-mitigating site grading—meeting strict FEMA and ICC-600 standards for coastal resilience.

- Nordic mountain builders integrate thermal breaks, snow-load-optimized roof pitches, and vapor-open wall systems to prevent ice damming and interstitial condensation in sub-zero, high-snowfall environments.

- Colorado desert contractors specify thermal expansion joints, UV-stabilized coatings, and reflective roofing to manage extreme diurnal swings—up to 40°F daily—without compromising envelope continuity.

- Pacific Northwest teams deploy moisture-wicking rainscreen cavities, mold-resistant sheathing, and bio-based air barriers calibrated for persistent rainfall and high humidity in temperate rainforests.

This hyper-localized execution prevents costly retrofits, ensures code compliance in challenging jurisdictions, and delivers performance that generic prefab systems cannot match—making regionally vetted expertise essential for scenic location success.

Table of Contents

- Climate-Resilient Design: Engineering Durability for Scenic Environments

- Material Intelligence: Sustainable, Local, and High-Performance Choices for Prefab Homes

- Lifecycle Value: Why Upfront Investment in Durable Prefab Home Systems Pays Off Long-Term

- Builder Selection and Site Integration: Ensuring Real-World Performance in Remote Scenic Locations