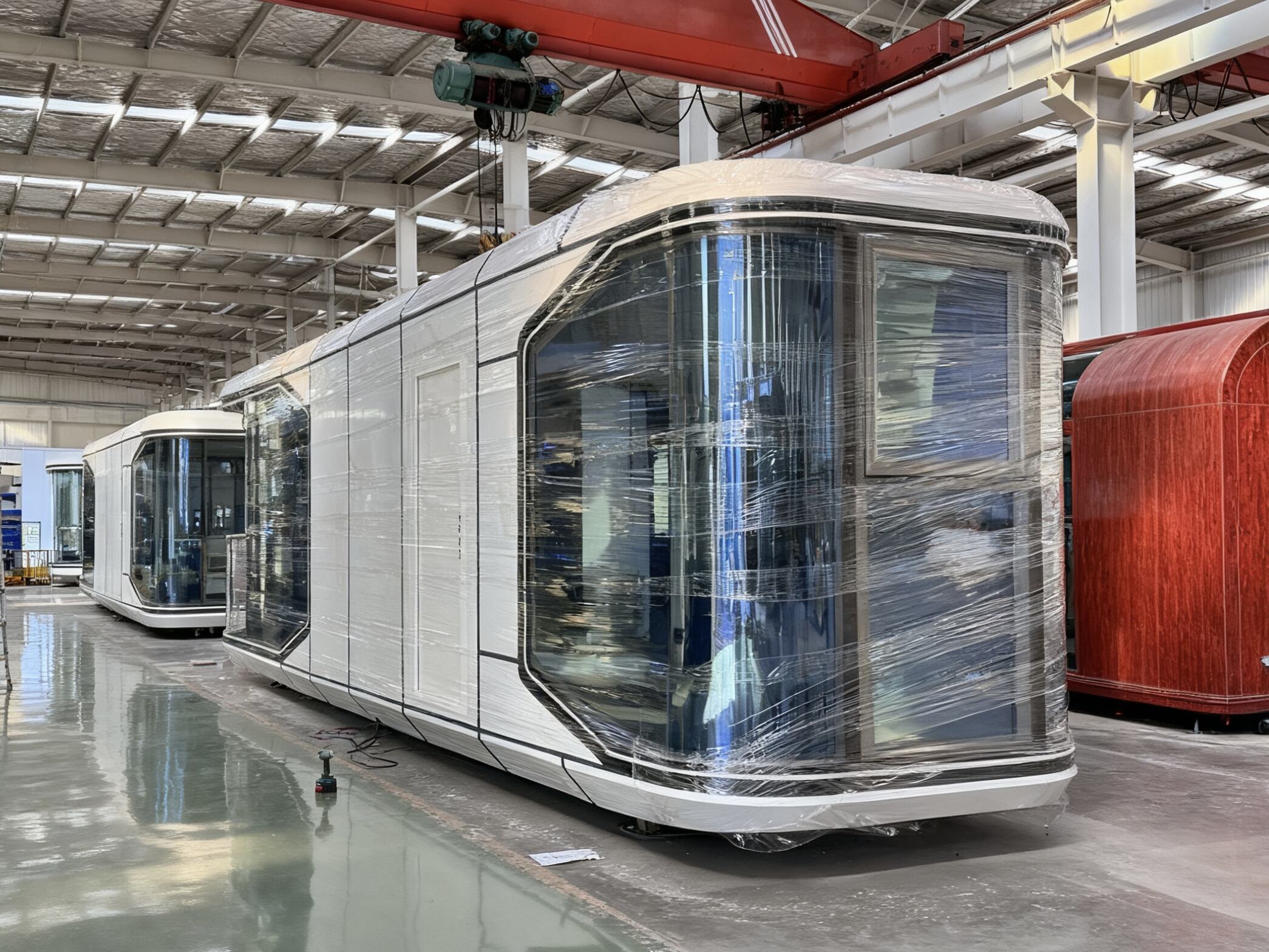

Why Steel Structure Cabin Excel in Extreme Weather Resistance

Material Advantages: Strength-to-Weight Ratio, Ductility, and Non-Combustibility

Steel cabin structures rely on three key material characteristics that make them stand out in harsh weather conditions. First off, they have an impressive strength to weight ratio which means the frames are strong yet light enough so they don't get blown away in hurricanes while still maintaining stability. Steel also has this quality called ductility that lets it bend and flex when winds get really strong instead of snapping apart like some other materials do. That's pretty important because it absorbs all that force without breaking. Another big plus is steel doesn't burn, making these cabins much safer in places prone to wildfires where wooden buildings catch fire so easily. All these features combined mean steel structures aren't just built to survive bad weather events, they actually keep working properly even when nearby buildings might be damaged or destroyed completely.

Steel vs. Traditional Materials: Real-World Performance in Tornadoes, Hurricanes, and Floods

In actual extreme weather events, steel cabins consistently outperform wood and concrete alternatives:

- Tornadoes: Properly anchored steel frames resist EF3-level winds (136–165 mph) by distributing lateral forces through rigid, continuous connections—avoiding the roof detachment and wall collapse common in wood-frame buildings.

- Hurricanes: Galvanized steel components withstand salt-laden 150+ mph gusts and resist corrosion far longer than timber, which warps with moisture and fails under projectile impact.

- Floods: Elevated steel foundations and fully sealed envelopes prevent infiltration, unlike porous concrete that deteriorates under repeated saturation cycles. Field evidence shows steel structures surviving typhoons equivalent to Category 4 intensity with only minor reinforcement—while conventional builds suffer irreparable damage.

This reliability stems from steel’s uniformity: consistent mechanical properties enable precise, predictable engineering responses—even as storm intensity and frequency increase.

Engineering Steel Structure Cabins for Specific Extreme Weather Threats

Tornado & High-Wind Resilience: Bracing, Anchorage, and EF3-Compatible Design

What makes buildings stand up against tornadoes isn't just about using strong materials, it's really about how everything works together as a system. Think about those special bracing systems that actually direct wind forces throughout the whole structure, plus those continuous load paths running all the way from the roof down to the ground. And don't forget the deep anchors going into reinforced concrete footings that can handle winds pushing up with force over 150 miles per hour. When we talk about EF3 rated designs, these include extra strong connection points and special connectors tested to survive wind pressures well over 200 pounds per square foot. Just to put this in perspective, regular wood frame buildings start showing cracks when faced with pressures above 100 psf. That's why steel structures with their built-in redundancies are so critical for keeping people safe during extreme weather events.

Flood Adaptation: Elevated Foundations, Sealed Envelopes, and Corrosion-Resistant Systems

Steel cabins built in areas prone to flooding typically sit on piers raised well above what's considered the base flood level. This design choice basically removes any risk from direct contact with floodwaters on the ground. For the main structural parts, builders go with hot dip galvanized steel coated with a special zinc aluminum alloy mixture that's around 350 microns thick. This coating gives about three times better protection against rust compared to regular paint jobs we see elsewhere. When it comes to keeping everything watertight, the building envelope has welded seams throughout, plus waterproof membranes and those sealed joints with gaskets. All this works together so the structure stays intact even when submerged. And here's something interesting: unlike traditional materials like wood or plain concrete, these steel structures actually keep their strength intact after being underwater for extended periods. We've seen this time and again through inspections done after major floods along coastlines and near rivers where these buildings have stood up remarkably well despite all the water damage.

Wildfire & Hurricane Mitigation: Non-Combustible Cladding, Impact-Resistant Openings, and FEMA P-361 Alignment

- Non-combustible cladding, such as steel sheathing or mineral wool boards, remains stable at temperatures exceeding 1,200°F—eliminating ignition pathways during ember showers and radiant heat exposure.

- Impact-resistant openings combine laminated glass with polyvinyl butyral (PVB) interlayers and steel-reinforced frames, tested to stop windborne debris traveling at 130 mph—the benchmark for hurricane-prone regions.

- All critical structural details align with FEMA P-361 standards, including continuous load paths, redundant fastening, and load-transfer redundancy proven to sustain Category 4 hurricane conditions.

Long-Term Durability: Protective Finishes and Maintenance for Steel Structure Cabins

Galvanization, Zinc-Aluminum Coatings, and Ceramic Sealants for All-Climate Protection

The lifespan of metal structures really starts from what's on the outside. Hot dip galvanization creates a strong zinc layer that bonds to steel and actually sacrifices itself to protect the metal, even those tricky cut edges. That makes it great for places near the coast or anywhere with lots of humidity. The newer zinc aluminum alloy coatings take things one step better. Aluminum in these mixes acts as a shield against those pesky chloride ions, while the zinc part keeps doing its job protecting the steel underneath. Lab tests show these special alloys can last two to three times longer than regular galvanizing treatments. Then there are ceramic sealants which form the last defense line. These create surfaces that push away water, resist UV damage, and stand up to temperature changes over time. Putting all these together means structures can stay intact for over fifty years in normal weather conditions, something we've seen in many real world examples of galvanized steel buildings standing strong through decades. Regular checks once a year and fixing any spots where the coating gets damaged, particularly around welds and bolts, will stop corrosion from getting started beneath the surface. In tougher environments like factories or near saltwater, combining hot dip galvanization with ceramic coatings gives the best protection with minimal need for ongoing maintenance.